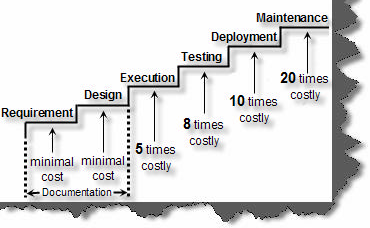

If a defect is known at the initial stage then it should be removed during that stage / phase itself rather than doing it some later stages. It’s a recorded fact that if a defect is delayed for later phases are proven more costly. Below figure shows how a defect is costly as the phase moves ahead. A defect if identified and removed during the requirement and design phase is the most cost effective, while a defect removed during maintenance is 20 times costlier than requirement and design phases. For instance if a defect is identified during requirement and design we only need to change documentation , but if identified during the maintenance we not only need to fix the defect , but also change our test plans , do regression testing and change all documentation for the same. This is why a defect should be identified / removed in earlier phases and the testing department should be involved right from the requirement phase and not after the execution phase.

Cost of defect increases with phase

Cost of defect increases with phase